Three-layered composite hollow fiber membrane capsule filter for degassing and aeration

Model No.

20M0060A

|

Capsule |

| Effective Membrane Area |

0.6 m2 |

| Dimentsions |

Length |

200 mm |

| Maximum Outer Diameter |

61 mm |

| Material |

Case |

Polycarbonate |

| Cap |

Polycarbonate |

| Sealant |

Polyurethane |

| Maximum Operating Pressure |

≦ 0.3 MPa |

| Operating Temperature Range |

1- 40 ℃ |

| Connection Type |

Screw |

| Connection size |

G 1/4 (PF 1/4) |

Three- layered composite hollow fiber membrane filter

cartridge for degassing and aeration

Model No.

20E0240A3

|

Cartridge |

| Effective Membrane Area |

2.4 m2 |

| Dimentsions |

Length |

215 mm |

| Maximum Outer Diameter |

72 mm |

| Material |

Case |

Polycarbonate |

| Cap |

- |

| Sealant |

Polyurethane |

| Maximum Operating Pressure |

≦ 0.3 MPa |

| Operating Temperature Range |

1- 40 ℃ |

| Connection Type |

- |

| Connection size |

- |

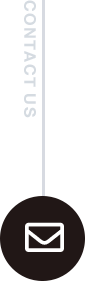

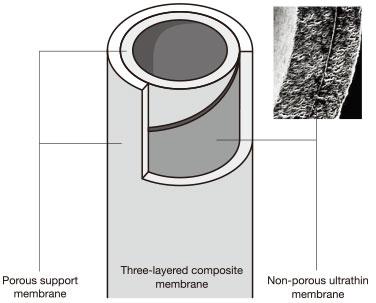

- Three-layered Composite Membrane

- This revolutionary membrane transmits only the gases dissolved in liquids, responding to needs in degassing and aeration

applications.

Key Features of Three-layered Composite Membrane Module

- ◆ An Extensive Product Lineup

- These products are available in a wide range of sizes.

- ◆ High Performance with Compact Size

- The hollow fiber shape permits high density while the three-layered composite hollow fiber membrane delivers excellent

gas transmission. The result is a modular structure that secures high performance with compact size.

- ◆ Stable Running Performance

- On-line design achieves suitable degassing and aeration performance.

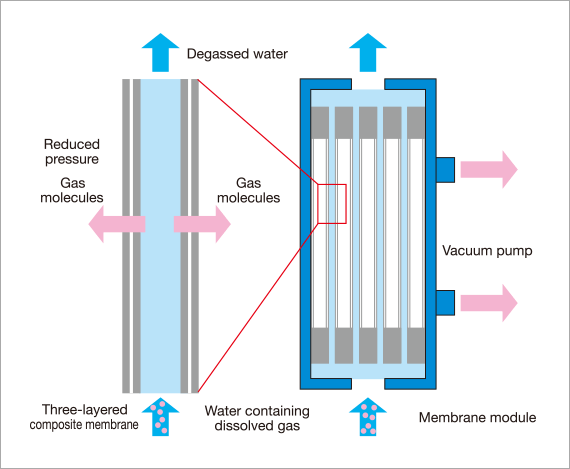

Degassing and Aeration Systems

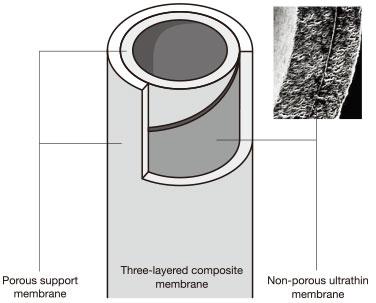

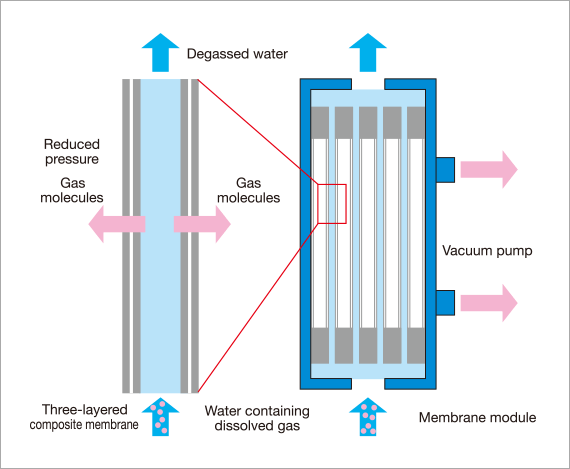

Gas permeation through the non-porous membrane is driven by the gas concentration difference across the membrane.

This membrane allows only gas molecules to permeate by dissolution / diffusion mechanism.

- Degassing mechanism

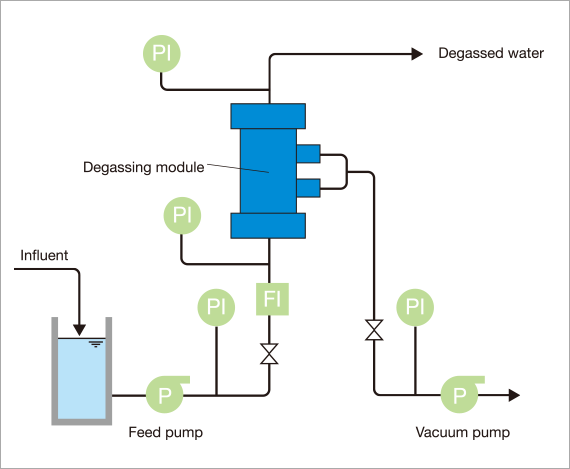

- Process flow diagram

Applications

| Applications |

Functions |

Effects |

| Ultrapure water for cleaning LSI chips, LCD cleaning |

Dissolved oxygen removal

Dissolved carbon dioxide removal |

Oxide film prevention

Polisher (ion exchange resin) load reducation |

| Feed water and air conditioning water |

Dissolved oxygen removal |

Water line corrosion prevention |

| Food and beverage prosessing water |

Dissolved air removal |

Improves oxidation degration prevention |

| Ultrasonic cleaning water |

Dissolved oxygen removal

Dissolved air removal |

Prevents corrosion of metal parts

Improves strength of sonic cleansing action |

| Water for analytical instruments |

Debubbling |

Improvement accuracy of quantitative microanalysis |

We can design the water / air treatment system that best suits your needs.

Contact Cleansui for industrial solutions.